Ideal Supplier for Micro Hematocrit Centrifuge

Ideal Manufacturer for Micro Hematocrit Centrifuge

What is Micro Hematocrit Centrifuge?

A Micro Hematocrit Centrifuge is a specialized piece of laboratory equipment used primarily in clinical settings for the rapid determination of the hematocrit (HCT) value of blood samples. Hematocrit is the percentage of red blood cells in a blood sample, a critical parameter in diagnosing and monitoring various medical conditions such as anemia, dehydration, and polycythemia.

Development Histroy of Micro Hematocrit Centrifuge

The first centrifuge, developed by Antonin Prandtl in 1864, was a cream separator used in dairy processing. In the late 19th and early 20th centuries, the use of centrifugation in laboratories became more widespread. However, these early machines were large, cumbersome, and not specifically designed for hematocrit determination.

1950s: Emergence of the Micro Hematocrit Centrifuge

The 1950s marked a significant period in the development of hematocrit measurement. Researchers and engineers began designing centrifuges specifically for determining hematocrit levels.

The introduction of micro hematocrit tubes, thin capillary tubes specifically designed for this purpose, was a key innovation.

1960s-1970s: Widespread Adoption

By the 1960s and 1970s, the Micro Hematocrit Centrifuge had become a standard piece of equipment in clinical laboratories. Its compact design, combined with its ability to deliver quick and accurate results, made it indispensable for routine blood testing. The growing use of hematology in diagnostic medicine further drove the adoption of these centrifuges.

1980s-2000s: Digital Enhancements and Automation

With the advent of digital technology in the 1980s, Micro Hematocrit Centrifuges began to incorporate digital controls and displays. These enhancements allowed for more precise control of centrifugation parameters such as speed and time, leading to even more accurate hematocrit measurements.

The integration of automated features, such as preset programs and automatic lid locking mechanisms, improved safety and ease of use. These advancements made the centrifuges more user-friendly and reduced the risk of errors during operation.

2010s-Present: Continued Innovation

In the 21st century, continued innovation in materials science, electronics, and automation has further refined the design and function of Micro Hematocrit Centrifuges. Modern centrifuges are highly reliable, easy to operate, and capable of delivering rapid results with minimal sample volume.

Current models often feature enhanced safety mechanisms, such as imbalance detection and automatic shutdown, to protect both the user and the equipment. Advances in rotor design have also increased the capacity and speed of these centrifuges, allowing for faster processing times and greater throughput in busy clinical environments.

Key Features of a Micro Hematocrit Centrifuge

Compact Design, Size: Typically small and lightweight.

Portability: Easy to move between different workstations or laboratories.

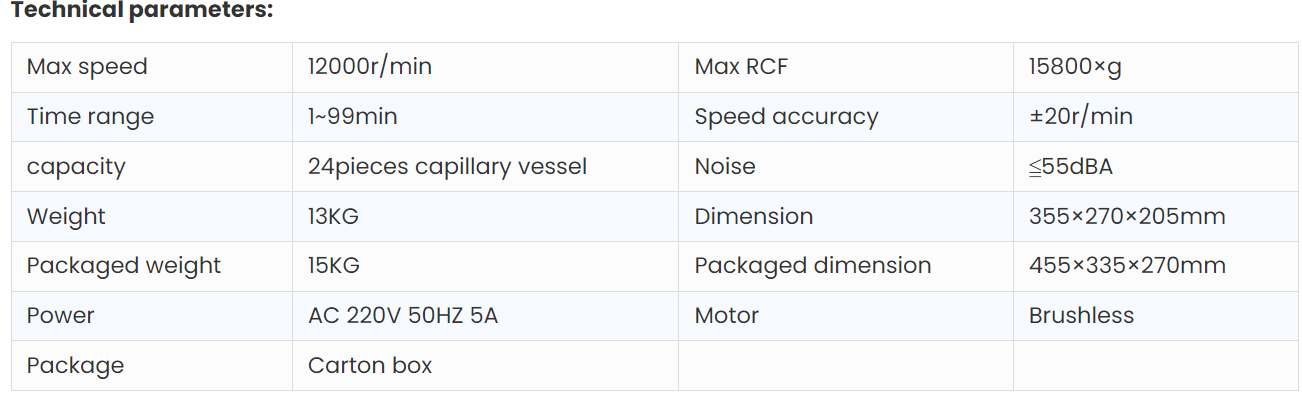

High Speed, RPM (Revolutions Per Minute): often ranging between 10,000 to 15,000 RPM, to ensure rapid separation of blood components.

Specialized Rotor, Fixed-Angle Rotor: Designed specifically to hold capillary tubes (also known as microhematocrit tubes) at a fixed angle, typically around 90° to the axis of rotation.

Capacity: Can hold multiple capillary tubes simultaneously, usually 12 to 24 tubes, depending on the model.

Safety Features, Lid Locking Mechanism: Prevents the lid from being opened while the rotor is spinning, ensuring operator safety.

Easy-to-Use Interface

Digital or Analog Controls: Features user-friendly controls for setting speed and time, with clear displays for monitoring the process.

Timer Function: Allows precise timing of centrifugation cycles, usually adjustable up to several minutes.

Typical Micro Hematocrit Centrifuges from our company

Key conponents for Micro Hematocrit Centrifuge

1. Rotor

Fixed-Angle Rotor: The rotor is the central component of the centrifuge that holds the capillary tubes.

Material: Rotors are usually made from durable, corrosion-resistant materials such as aluminum or composite materials to withstand high speeds and the stresses of repeated use.

2. Capillary Tube Holders

Tube Slots: These are specifically designed slots within the rotor to hold the microhematocrit capillary tubes securely in place during centrifugation. The number of slots varies depending on the model, typically accommodating 12 to 24 tubes.

Balancing: The tube holders are designed to ensure that the rotor is balanced during operation, preventing vibrations and ensuring consistent results.

3. Lid

Safety Lid with Locking Mechanism: The lid covers the rotor and ensures that the capillary tubes remain in place during centrifugation. It is equipped with a locking mechanism to prevent the lid from being opened while the rotor is spinning, ensuring user safety.

4. Motor

High-Speed Motor: The motor powers the rotor, driving it at high speeds, typically between 10,000 and 15,000 RPM.

Brushless Motor Technology: Modern centrifuges often use brushless motors, which are quieter, more efficient, and require less maintenance compared to traditional brushed motors.

5. Control Panel

Speed and Time Controls: The control panel allows the operator to set the centrifuge's speed (RPM) and duration of the run. This can be either digital or analog, depending on the model.

Display Screen: A digital display provides real-time information on the current speed, time remaining, and other operational parameters, helping ensure accurate and repeatable results.

6. Imbalance Detection System

Safety Feature: This system detects any imbalance in the rotor during operation, which could cause excessive vibration or damage to the centrifuge. If an imbalance is detected, the system automatically stops the centrifuge to prevent accidents and equipment damage.

7. Capillary Tube Reader (Optional)

Hematocrit Reader: Some Micro Hematocrit Centrifuges include or are paired with a capillary tube reader, which is a device used to measure the packed cell volume (PCV) or hematocrit after centrifugation. This reader allows for accurate, direct reading of the hematocrit level in the capillary tubes.

These components work together to ensure that a Micro Hematocrit Centrifuge performs its function efficiently, safely, and reliably.

Industries used for Micro Hematocrit Centrifuge

1. Healthcare and Clinical Laboratories

Hospitals: Micro Hematocrit Centrifuges are commonly used in hospital laboratories for routine blood tests. They are essential for diagnosing and monitoring conditions such as anemia, dehydration, and polycythemia.

Diagnostic Laboratories: Independent diagnostic labs use these centrifuges to perform hematocrit tests as part of complete blood count (CBC) panels, providing critical information for patient diagnosis and treatment.

Emergency Care: In emergency settings, where rapid diagnostic decisions are crucial, Micro Hematocrit Centrifuges enable quick assessment of a patient’s hematocrit level, which can be vital in cases of trauma, severe dehydration, or blood loss.

2. Blood Banks and Donation Centers

Blood Donation Screening: Blood banks use Micro Hematocrit Centrifuges to screen donors. The hematocrit level is checked to ensure donors have sufficient red blood cell concentration before donating, preventing adverse effects on donor health.

Component Separation: While microcentrifuges are not typically used for large-scale blood processing, they are valuable in initial screenings and smaller, focused tasks within the blood banking process.

3. Animal Medicine

Animal Clinics and Hospitals: Veterinary clinics use Micro Hematocrit Centrifuges to diagnose and monitor hematological conditions in animals. Rapid determination of hematocrit levels is crucial for the treatment of pets, livestock, and wildlife.

Research and Testing: In veterinary research, these centrifuges help in studying animal diseases, blood disorders, and the effects of various treatments on blood parameters.

4. Research Laboratories

Biomedical Research: Research institutions use Micro Hematocrit Centrifuges in studies involving blood samples from humans or animals. They are crucial for experiments that require precise measurement of red blood cell concentration and other blood components.

Hematology Studies: Researchers studying blood disorders or developing new treatments for blood-related conditions rely on Micro Hematocrit Centrifuges to provide accurate hematocrit readings.

5. Military and Field Medical Units

Field Hospitals: In military or remote field medical units, Micro Hematocrit Centrifuges are used for on-site blood testing. Their portability and rapid processing capabilities make them ideal for use in environments where quick, reliable blood analysis is needed.

Medical Evacuation: During medical evacuations, these centrifuges help in assessing the severity of a patient’s condition, particularly in cases of severe blood loss or shock.

6. Educational Institutions

Medical and Veterinary Schools: Educational institutions use Micro Hematocrit Centrifuges as teaching tools in laboratory courses. Medical and veterinary students learn to operate these centrifuges as part of their training in hematology and clinical diagnostics.

Research Training: Universities and colleges may use these centrifuges in research training programs, allowing students to gain hands-on experience in blood analysis techniques.

7. Pharmaceutical Industry

Drug Testing and Development: Pharmaceutical companies use Micro Hematocrit Centrifuges in the development and testing of new drugs, particularly those that affect blood parameters. Accurate hematocrit measurements are crucial in assessing the efficacy and safety of these medications.

What should take care when use Micro Hematocrit Centrifuge?

1. Preparation and Inspection

Check the Equipment: Before use, inspect the centrifuge for any visible damage, such as cracks in the rotor, wear on the lid, or loose components. Ensure that the centrifuge is clean and free of any debris or contaminants.

Verify Rotor Compatibility: Ensure that the rotor installed is the correct type for hematocrit tubes and that it is securely attached. Using the wrong rotor or an improperly installed rotor can lead to imbalanced operation and potential damage.

Inspect Capillary Tubes: Examine the capillary tubes for cracks, chips, or other defects before placing them in the rotor. Damaged tubes can break during centrifugation, posing a risk to both the sample and the operator.

2. Balancing the Rotor

Load Capillary Tubes Evenly: To avoid imbalances, always load an even number of capillary tubes, evenly distributed across the rotor. If an odd number of samples is being processed, use a balance tube filled with water or another non-reactive substance to counterbalance the rotor.

Check for Symmetry: Double-check that the tubes are placed symmetrically. An imbalanced rotor can cause vibrations, noise, and potentially lead to mechanical failure or inaccurate results.

3. Setting the Speed and Time

Follow Manufacturer’s Guidelines: Set the centrifuge’s speed (RPM) and time according to the manufacturer’s recommendations for hematocrit measurements. Operating the centrifuge at the wrong speed can lead to inaccurate separation of blood components or damage to the centrifuge.

Avoid Overloading: Do not exceed the recommended number of tubes or the centrifuge's maximum capacity, as this can strain the motor and rotor, leading to possible malfunction.

4. Operation Safety

Close the Lid Securely: Ensure that the centrifuge lid is securely closed and locked before starting the operation. The centrifuge should not be operated with the lid open, as this can lead to accidents, such as flying debris if a tube breaks.

Stay Clear During Operation: Once the centrifuge is running, avoid leaning over or placing any objects on the lid. Stay clear of the centrifuge until it has come to a complete stop.

Monitor for Unusual Sounds: Pay attention to any unusual noises or vibrations during operation. If the centrifuge is making excessive noise or vibrating, it could indicate an imbalance or a mechanical issue. Stop the centrifuge immediately and check for problems.

5. Post-Operation Care

Wait for Complete Stop: Allow the rotor to come to a complete stop before opening the lid. Never attempt to stop the rotor manually by touching it or using any object, as this can be extremely dangerous.

Carefully Remove Tubes: After the centrifuge has stopped, carefully remove the capillary tubes from the rotor. Handle them gently to avoid breakage and contamination.

Clean the Rotor and Chamber: After each use, clean the rotor and the centrifuge chamber to remove any residue or spills. Use appropriate cleaning solutions recommended by the manufacturer to avoid damaging the centrifuge components.

6. Maintenance and Storage

Regular Maintenance: Perform regular maintenance as recommended by the manufacturer, such as lubricating moving parts, checking the rotor for wear, and ensuring that the motor is functioning properly.

Store Properly: When not in use, store the centrifuge in a clean, dry, and dust-free environment. Ensure the lid is closed to prevent dust and debris from entering the chamber.

Calibration and Testing: Periodically check the calibration of the centrifuge to ensure it is operating at the correct speeds and providing accurate results. Regularly test the imbalance detection system to ensure it functions correctly.

7. Safety Precautions

Use in a Controlled Environment: Operate the centrifuge in a stable, vibration-free environment to ensure it runs smoothly. Avoid placing the centrifuge on uneven surfaces or near equipment that could cause interference.

Follow Safety Protocols: Adhere to all laboratory safety protocols, including wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses when handling blood samples and operating the centrifuge.

Electrical Safety: Ensure that the centrifuge is plugged into a properly grounded outlet that meets the voltage requirements specified by the manufacturer. Avoid using extension cords or adapters that could cause electrical faults.

8. Handling Samples and Waste

Proper Sample Handling: Handle all blood samples with care to prevent spills and contamination. Label all samples clearly to avoid mix-ups.

Disposal of Waste: Dispose of used capillary tubes and any other waste according to biohazard disposal protocols. Do not discard tubes or other potentially infectious materials in regular trash.

How to control the quality during manufacturing of the Micro Hematocrit Centrifuge?

1 . Design and Engineering

Precision Engineering: The design phase focuses on creating a centrifuge that meets the specific requirements for micro hematocrit applications, including rotor design, speed, and capacity. Engineering controls ensure that all parts fit together precisely and function correctly under high-speed operation.

Material Selection: Selecting high-quality, durable materials for the rotor, housing, and internal components is crucial. These materials must withstand high-speed rotation and the resulting forces, as well as resist corrosion and wear.

2. Rotor Balancing

Dynamic Balancing: The rotor is a critical component that must be perfectly balanced to prevent vibrations during operation. Dynamic balancing is performed during manufacturing to ensure that the rotor remains stable even at high speeds, which is crucial for accurate and consistent results.

Tolerance Checks: Strict tolerance checks are carried out on the rotor to ensure it meets the design specifications and can handle the centrifugal forces generated during operation.

3. Motor Assembly and Calibration

High Speed Motor Testing: The motor is tested for speed, power output, and reliability. It must be capable of reaching and maintaining the required RPMs for hematocrit separation without overheating or failing.

Calibration: The motor is calibrated to ensure that it operates within the specified speed range and that the control system accurately regulates its performance. Calibration ensures that the centrifuge delivers consistent and repeatable results.

4. Safety Mechanisms

Lid Locking System: The safety of the user is paramount, so the lid locking system is rigorously tested to ensure it cannot be opened while the rotor is spinning. This prevents accidents and exposure to potentially hazardous materials.

Imbalance Detection: The imbalance detection system is tested to ensure it can accurately detect rotor imbalances and automatically shut down the centrifuge to prevent damage or accidents.

5. Electrical and Control Systems

Circuit Integrity Testing: The centrifuge’s electrical system, including the control panel and power supply, is tested for integrity, ensuring there are no short circuits or faults that could affect performance or safety.

User Interface Testing: The control panel, including speed and time settings, is tested for accuracy and responsiveness. This ensures that users can easily and accurately set the desired parameters for each run.

6. Temperature Control (for refrigerated models)

Cooling System Testing: For refrigerated Micro Hematocrit Centrifuges, the cooling system is tested to ensure it can maintain the required temperature range during operation. This is critical for preserving the integrity of temperature-sensitive samples.

Thermostat Calibration: The thermostat is calibrated to ensure precise temperature control, preventing fluctuations that could affect sample quality.

7. Component and Material Quality Control

Incoming Material Inspection: All materials and components used in the centrifuge, such as the rotor, housing, and electrical parts, are inspected upon arrival to ensure they meet quality standards. Any substandard materials are rejected.

Supplier Certification: Manufacturers typically work with certified suppliers to ensure that components meet stringent quality and performance standards.

8. Final Assembly and Testing

Functional Testing: After assembly, each centrifuge undergoes a series of functional tests to ensure all components work together as intended. This includes running the centrifuge at various speeds and durations to verify performance.

Quality Assurance (QA) Inspections: A final QA inspection is conducted to check for any defects, inconsistencies, or deviations from the design specifications. This includes visual inspections, performance tests, and safety checks.

9. Compliance with Standards

Regulatory Compliance: The manufacturing process must comply with relevant international standards and regulations, such as ISO and CE certifications. This ensures that the centrifuge meets global safety and performance criteria.

Documentation and Traceability: Comprehensive documentation is maintained throughout the manufacturing process, allowing for traceability of each component and ensuring that any issues can be traced back to their source.

10. Packaging and Shipping

Protective Packaging: it should be carefully packaged to protect it during shipping. Packaging materials are selected to cushion the centrifuge and prevent damage during transit.

Final Inspection: Before shipping, a final inspection ensures that the centrifuge is in perfect condition and all accessories (e.g., capillary tubes, adapters) are included.

11. After-Sales Support:

We will provide technical support and service options to help customers with installation, calibration, and maintenance, ensuring the centrifuge continues to operate at peak performance.

If you need customized Micro Hematocrit Centrifuge, you can email to us for more details.

Hot selling centrifuges you may interested in